This event is hosted by Eric Schupp

Location: 30 Echo Lake Road, Watertown CT, 06795

Time: 9:30AM to 6:00PM

Good day fellow Makers! January 14th CTH will be doing a 3d printing meet up. Starting at 9:30am and running till 6pm. We will be chatting about 3d printers and projects. Feel free to bring your own printers if you have questions, want to show off what you are working on, etc.

Don’t have a 3d printer? No problem, stop on in to ask about what 3d printing is and advice on where to start. Donations to support CTH doing these meet ups in the future, are welcome. See ya there!

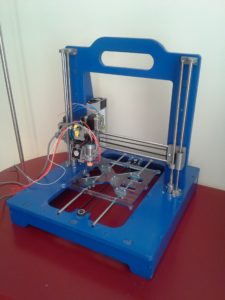

The 27-May 3D Printer Workshop at CTH went well. Our new pal Josh brought in his older AirWolf 3D AW3D XL printer. This thing has a huge 200×300 mm heated build plate. However, the build plate was a PCB-style which flexed and warped when heating up. This gave an inconsistent print surface height. If you’ve printed before, you know the height of the print surfaces has to be pretty darn consistent to get first-layer adhesion. Josh bought a replacement aluminum build plate, but unfortunately, the mounting holes were not the same! We can fix that…

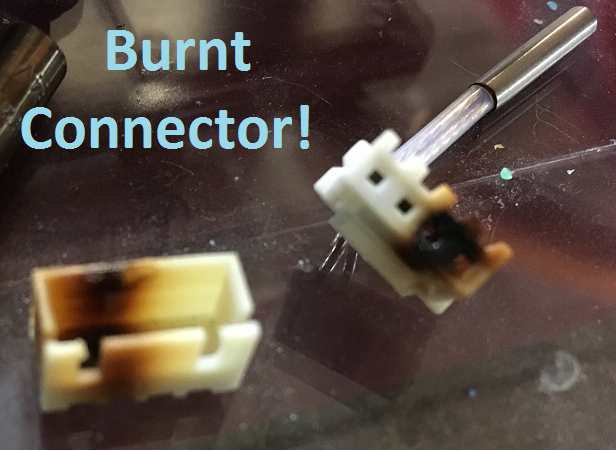

The 27-May 3D Printer Workshop at CTH went well. Our new pal Josh brought in his older AirWolf 3D AW3D XL printer. This thing has a huge 200×300 mm heated build plate. However, the build plate was a PCB-style which flexed and warped when heating up. This gave an inconsistent print surface height. If you’ve printed before, you know the height of the print surfaces has to be pretty darn consistent to get first-layer adhesion. Josh bought a replacement aluminum build plate, but unfortunately, the mounting holes were not the same! We can fix that…  My beloved Afinia H-Series 3D Printer has not been working for several weeks. The bed would not heat up and the printer would not start printing because the bed was not up to temperature. I took the opportunity at the CTH 3D Printer Workshop to troubleshoot the Afinia. Well, I found the cause after a little disassembly. Do you see a problem here????

My beloved Afinia H-Series 3D Printer has not been working for several weeks. The bed would not heat up and the printer would not start printing because the bed was not up to temperature. I took the opportunity at the CTH 3D Printer Workshop to troubleshoot the Afinia. Well, I found the cause after a little disassembly. Do you see a problem here????

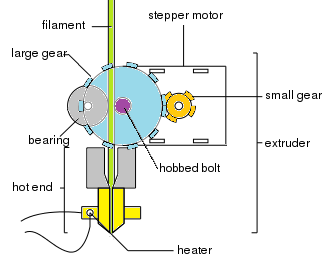

With the Wade-style RepRap 3D Printer extruders, the part that actually drives the filament is a ‘hobbed bolt’. A hobbed bolt has a little toothed-groove around its circumference that grips the filament and drives it into the hot-end as the bolt is turned. There’s a few ways to make a

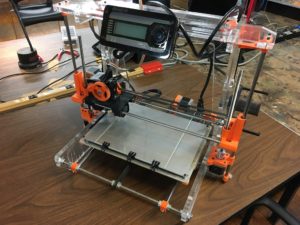

With the Wade-style RepRap 3D Printer extruders, the part that actually drives the filament is a ‘hobbed bolt’. A hobbed bolt has a little toothed-groove around its circumference that grips the filament and drives it into the hot-end as the bolt is turned. There’s a few ways to make a  Today I started a new 3D Printer build. I found what appears to be a great derivative of the Prusa i3, the

Today I started a new 3D Printer build. I found what appears to be a great derivative of the Prusa i3, the  Many members in our community recognize the full value in what open source can mean with a direct correlation to innovation. We are very excited to see that

Many members in our community recognize the full value in what open source can mean with a direct correlation to innovation. We are very excited to see that