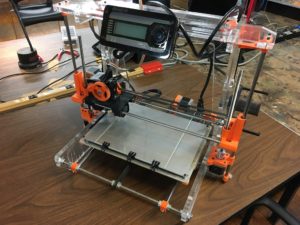

The 27-May 3D Printer Workshop at CTH went well. Our new pal Josh brought in his older AirWolf 3D AW3D XL printer. This thing has a huge 200×300 mm heated build plate. However, the build plate was a PCB-style which flexed and warped when heating up. This gave an inconsistent print surface height. If you’ve printed before, you know the height of the print surfaces has to be pretty darn consistent to get first-layer adhesion. Josh bought a replacement aluminum build plate, but unfortunately, the mounting holes were not the same! We can fix that…

The 27-May 3D Printer Workshop at CTH went well. Our new pal Josh brought in his older AirWolf 3D AW3D XL printer. This thing has a huge 200×300 mm heated build plate. However, the build plate was a PCB-style which flexed and warped when heating up. This gave an inconsistent print surface height. If you’ve printed before, you know the height of the print surfaces has to be pretty darn consistent to get first-layer adhesion. Josh bought a replacement aluminum build plate, but unfortunately, the mounting holes were not the same! We can fix that…

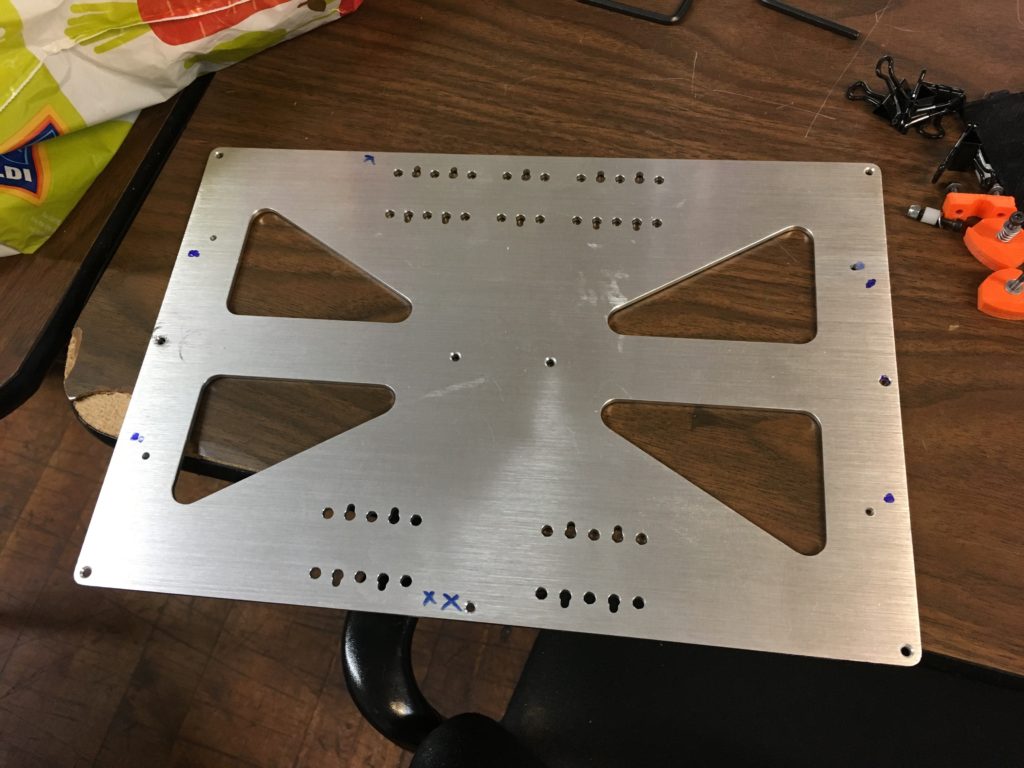

The build plate bolts directly to an aluminum frame. We removed that frame from the printer, clamped the new build plate to the frame and transfer-drilled new mounting holes in the frame. After that modification, re-assembly was a breeze.

This is the aluminum frame that we had to drill to accept the new Heated Build Plate

Along the way, an aluminum standoff was lost. Instead of heading to the hardware store, we just machined a replacement here out of some scrap aluminum. Having the tools and supplies to keep your project moving forward is one of the benefits of belonging to a hackerspace.

Original spacer on the left and the one we made at CTH on the right.

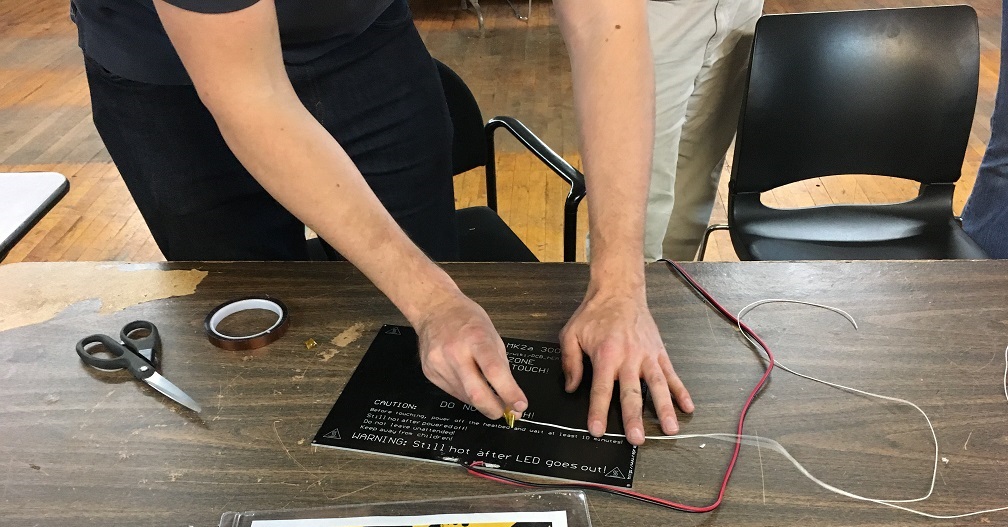

The new build plate came with a new thermistor and power wires. We swapped the connectors from the original, ran the new wires through the original wire loom and Bob’s your uncle. This AW3D XL now has a new and improved heated build plate that looks like it came that way from the factory.

If you’re interested in attending the next 3D Printer Workshop, make sure you join our Meetup group.

All Done!