A few days ago I posted how my wireless phone charging hack was a failure. I tried soldering in a Qi Receiver into my old school Samsung Galaxy Exhilarte SGH-i577 phone. While I got all the goodies crammed in the phone, the phone got waaaaay hot when charging. So much so that the phone gave a warning saying the battery is over-temp and charging was stopped!

A few days ago I posted how my wireless phone charging hack was a failure. I tried soldering in a Qi Receiver into my old school Samsung Galaxy Exhilarte SGH-i577 phone. While I got all the goodies crammed in the phone, the phone got waaaaay hot when charging. So much so that the phone gave a warning saying the battery is over-temp and charging was stopped!

Fast forward a couple days. I figured I could try a different charging pad. Guess what? It worked perfectly and the phone didn’t get hot! I can’t explain it. I’m not a Qi expert but I did poke around on Wikipedia to learn more about the Qi technology. From Wikipedia:

“Regulation of the output voltage is provided by a digital control loop where the power receiver communicates with the power transmitter and requests more or less power.”

There’s a new TV setup at the Bremster household. Flat screen on the wall with no visible wires. There’s one problem though, my WDTV media player. It’s small but still a tad too awkward to be precariously balanced on the top of the TV. Plus, the power, ethernet and HDMI cords sticking out the back don’t let the media player stay aligned with the TV. So what’s a dude to do? Design and 3D print a sweet bracket of course.

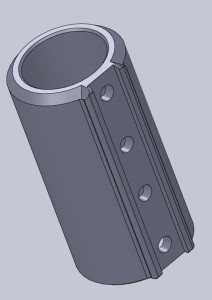

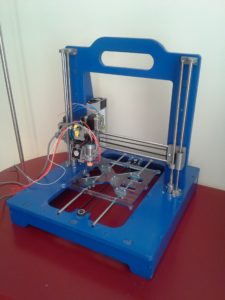

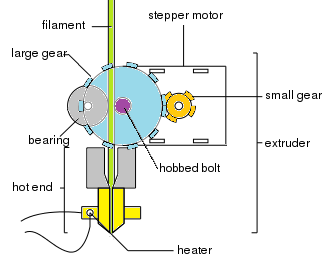

There’s a new TV setup at the Bremster household. Flat screen on the wall with no visible wires. There’s one problem though, my WDTV media player. It’s small but still a tad too awkward to be precariously balanced on the top of the TV. Plus, the power, ethernet and HDMI cords sticking out the back don’t let the media player stay aligned with the TV. So what’s a dude to do? Design and 3D print a sweet bracket of course.  With the Wade-style RepRap 3D Printer extruders, the part that actually drives the filament is a ‘hobbed bolt’. A hobbed bolt has a little toothed-groove around its circumference that grips the filament and drives it into the hot-end as the bolt is turned. There’s a few ways to make a

With the Wade-style RepRap 3D Printer extruders, the part that actually drives the filament is a ‘hobbed bolt’. A hobbed bolt has a little toothed-groove around its circumference that grips the filament and drives it into the hot-end as the bolt is turned. There’s a few ways to make a